Making new tools from recycled solid carbide consumes significantly less energy and produces far fewer CO₂ emissions than using virgin materials. With scarce critical resources like tungsten or cobalt, why mine unnecessarily?

Within the RemaNet project, a circular economy model for collaborative remanufacturing was developed and validated through an extensive machining case study by the partner institutions Mondragon Unibertsitatea and Wolco. Controlled tool life experiments were carried out on remanufactured cutting tools, monitoring tool wear, cutting forces, surface roughness, and overall machining performance. A robust validation methodology combining destructive and non-destructive analyses enabled the certification of remanufactured tools and the prediction of their remaining useful life (RUL).

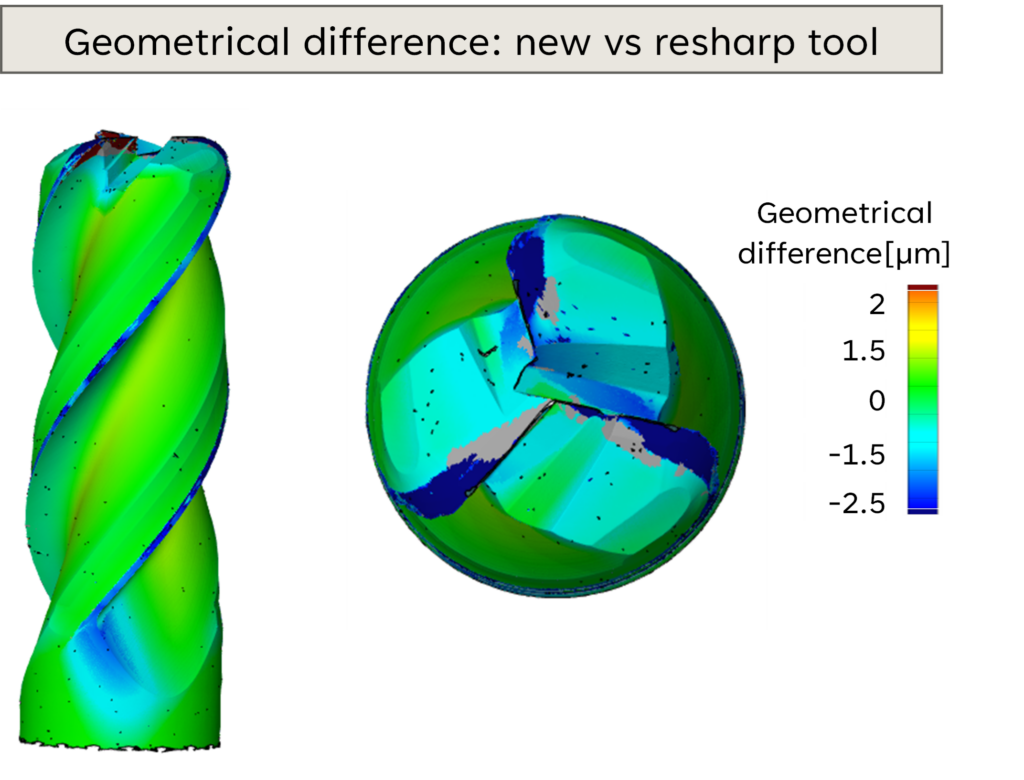

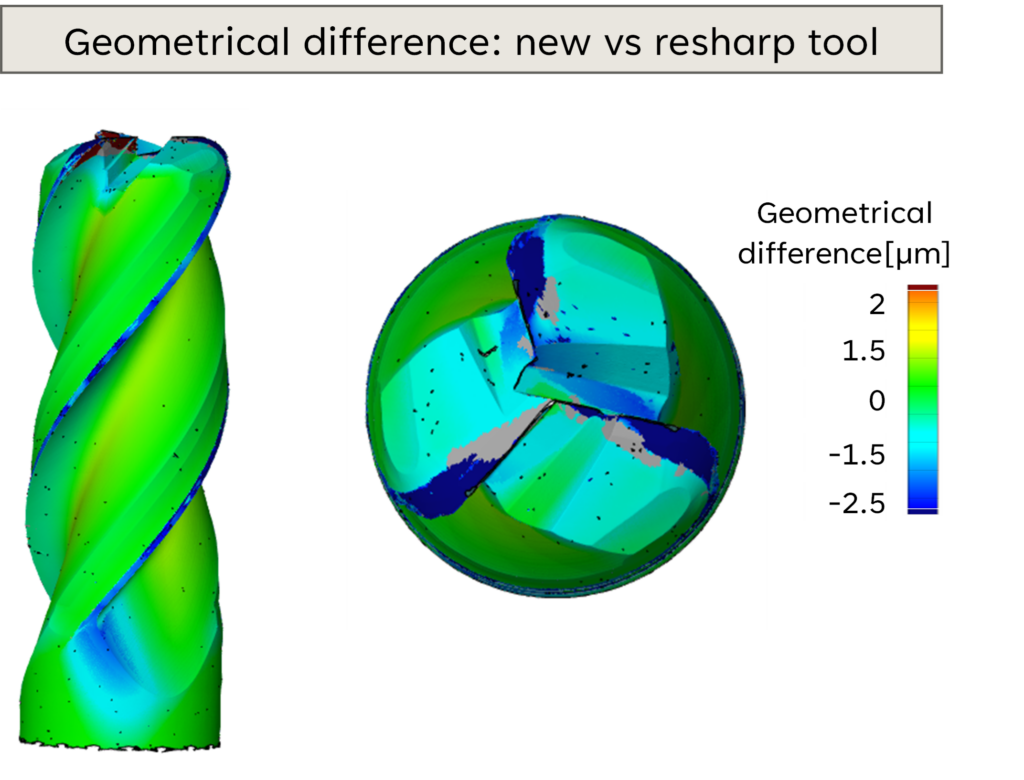

Results show the relevance of cutting edge preparation on tool life during the resharpening process, and that remanufactured tools maintain comparable workpiece quality to new tools. By tracking performance, energy consumption, and wear at each stage, a unique Digital Product Passport was established for each tool. This supported traceability and optimized resharpening cycles, making remanufacturing an economically viable alternative to replacement.

Milling tools example from software, for prediction of their remaining useful life (RUL):

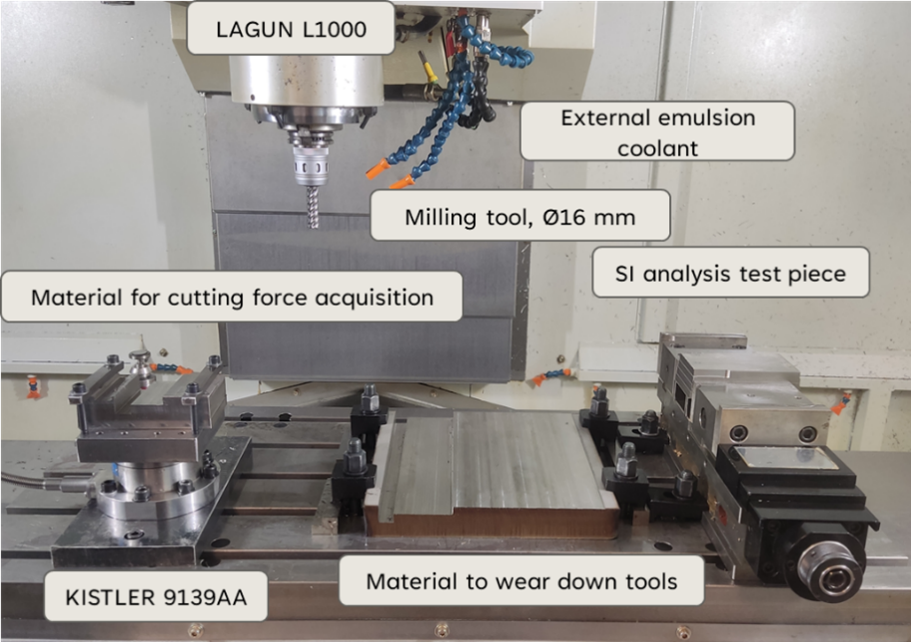

Milling experimental setup: